The Future of 3D Printing: Tech Innovations and Applications

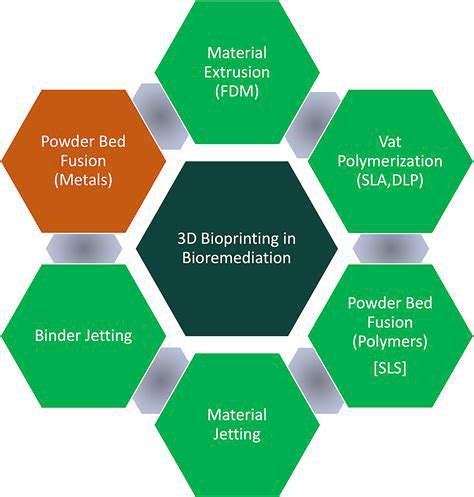

Bioprinting stands at the forefront of 3D printing technology, with the potential to revolutionize organ transplants. This process involves Layering Living Cells to create tissue-like structures, which can eventually lead to the production of functional organs. Current research shows promising results, with scientists able to print skin grafts and even simple organ tissues.

Surgical Planning and Simulation

- 3D printing aids in pre-surgical planning.

- Surgical simulations improve outcomes and reduce risks.

Surgeons can utilize 3D printed models of a patient's anatomy for surgical planning. This provides a tangible reference that enhances both understanding and communication among the surgical team. Procedures involving complex anatomies, such as cardiac or neurosurgery, particularly benefit from these printed models.

On-Demand Medical Supplies

3D printing also addresses the issue of inventory management in healthcare facilities. Hospitals can produce essential medical supplies on demand, significantly reducing the risk of shortages during crises. This capability was particularly demonstrated during the COVID-19 pandemic, when healthcare providers rapidly utilized 3D printing to manufacture personal protective equipment (PPE) and ventilator parts.

By streamlining the supply chain and reducing waste associated with traditional manufacturing, 3D printed medical supplies can offer substantial cost savings. Additionally, it opens the door to faster response times for emerging public health issues.

Sustainable Manufacturing Solutions

Advancements in 3D Printing Materials

One of the key drivers of sustainable manufacturing is the development of new, Eco-friendly materials for 3D printing. Recent innovations include bioplastics and recyclable materials, which can significantly reduce the carbon footprint of production processes. Research shows that using materials sourced from renewable resources can lead to a drastic reduction in dependence on fossil fuels.

Moreover, companies are exploring the use of composites that incorporate recycled plastics, which not only minimizes waste but also adds desirable properties to the prints. For example, using recycled PET in 3D printing processes can yield products that are both lightweight and durable, ultimately enhancing the life cycle of printed components.

Energy Efficiency in 3D Printing Processes

Energy consumption is a significant concern for sustainable manufacturing, and 3D printing presents opportunities for more efficient energy use. Advances in printer technology, specifically in terms of speed and material deposition, have led to a notable decrease in energy requirements during the printing process. For instance, companies implementing selective laser sintering (SLS) technologies have reported a 35% reduction in energy consumption compared to traditional manufacturing methods.

Waste Reduction and Recycling in 3D Printing

The ability of 3D printers to create objects layer by layer results in significantly less waste compared to subtractive manufacturing methods, which often cut away excess material. Research indicates that traditional machining processes can waste up to 80% of the original material used, while 3D printing can minimize this waste to less than 10%.

Furthermore, many companies are beginning to adopt closed-loop systems that allow for the recycling of failed prints or leftover filament into new printing materials. This practice not only mitigates waste but also adheres to the principles of a circular economy, emphasizing resource reuse.

On-Demand Production and Its Impact

3D Printing Technologies enable on-demand production, which contrasts starkly with the traditional manufacturing approach of overproduction and subsequent storage. This transformation not only conserves resources but also reduces the need for large warehouses, leading to lower overhead costs. According to recent analyses, companies utilizing on-demand techniques have reported up to a 50% decrease in inventory costs.

Customization and Its Role in Sustainability

One major advantage of 3D printing is the ease of customization, which allows manufacturers to tailor products to specific market needs without the inefficiencies of mass production. Customization can lead to reduced excess inventory since items are produced according to actual demand. A survey by industry experts found that 70% of manufacturers are interested in utilizing 3D printing for bespoke solutions to minimize waste related to unsold products.

Furthermore, personalized products often enjoy a longer shelf life and consumer satisfaction, which translates into reduced rates of disposal and overall waste generation.

Case Studies of Sustainable Manufacturing Innovations

Several companies across various industries have successfully implemented sustainable practices in their 3D printing processes. For instance, Adidas has integrated 3D printing technology to produce its Futurecraft series, which not only focuses on performance but also on reducing environmental impact by utilizing recyclable materials and innovative designs that require less material.

Similarly, the aerospace sector has embraced 3D printing for components, which can be manufactured to precise specifications while conserving material. Boeing, for example, has reduced waste by 90% in some parts of its supply chain through the adoption of additive manufacturing processes.

The Future Landscape of Sustainable Manufacturing

Looking forward, the integration of artificial intelligence and machine learning into 3D printing could bring about further efficiencies in material usage and design optimization. As technology evolves, these innovations are expected to fundamentally reshape the manufacturing landscape, making it more sustainable and cost-effective.

Moreover, as consumers increasingly prioritize sustainability, manufacturers who invest in eco-friendly 3D printing solutions are likely to gain a competitive edge, driving the industry toward greener practices. The continued collaboration between material scientists and engineers will play a crucial role in shaping this future.

Impact on the Aerospace and Automotive Industries

Advancements in 3D Printing Technologies

The aerospace and automotive industries are experiencing significant transformations due to advancements in 3D printing technologies. Notably, processes like selective laser sintering (SLS) and fused deposition modeling (FDM) have enabled firms to produce lightweight components with complex geometries, which are traditionally challenging to manufacture using conventional methods. These innovations not only streamline production but also minimize material waste, contributing to more sustainable practices.

As per a report by MarketsandMarkets, the 3D printing market in aerospace is projected to reach $7.6 billion by 2025—underlining the demand for efficient and cost-effective manufacturing processes. This trend is further fueled by the increasing adoption of additive manufacturing for creating customized parts that cater to specific operational needs in aircraft and vehicles.

Cost Reduction and Efficiency in Manufacturing

One of the primary impacts of 3D printing on the aerospace and automotive industries is the significant cost reduction associated with manufacturing processes. Traditional supply chains involve multiple steps, ranging from component sourcing to machining and assembly, which can be costly and time-consuming. In contrast, 3D printing allows for the production of a single, complex part in one step, reducing lead time and labor costs.

For example, Boeing has been leveraging 3D printing to produce parts for its aircraft, achieving significant savings by reducing the number of components needed. This streamlined approach not only cuts costs but also allows engineers to focus on innovation rather than repetitive manufacturing tasks.

Customization and Prototyping Advantages

3D printing offers unprecedented customization capabilities, allowing aerospace and automotive manufacturers to create bespoke components tailored to specific requirements. The ability to quickly iterate designs means that prototypes can be produced rapidly, enabling more efficient testing and development cycles. For instance, General Motors has reported a 50% reduction in prototyping timelines by implementing 3D printing techniques.

This aspect of additive manufacturing paves the way for enhanced designs that improve performance attributes, such as aerodynamics and fuel efficiency. Furthermore, companies can easily modify designs based on real-time feedback from test results without incurring substantial costs, thus accelerating the innovation cycle.

Material Innovations and Sustainable Practices

The advent of new materials suited for 3D printing is reshaping the landscape of both industries. Materials such as titanium, high-performance polymers, and even carbon fiber composites are being utilized to enhance the strength and durability of printed components. This allows manufacturers to produce parts that meet the rigorous standards set for safety and performance in aerospace and automotive applications.

Moreover, as industries aim to adopt more sustainable practices, 3D printing contributes significantly through reduced waste and the possibility of recycling materials post-use. Techniques such as powder recycling in metal 3D printing reduce the environmental impact of manufacturing by minimizing excess material consumption, making workflow processes greener overall.

Regulatory Considerations and Challenges

Despite the numerous advantages of 3D printing, regulatory hurdles remain a challenge, particularly in the aerospace sector where safety standards are paramount. Manufacturers must comply with stringent guidelines set by bodies such as the FAA and EASA when producing certified parts. This regulatory landscape can delay the wider adoption of 3D printing technologies, as extensive testing and validation are often required before a 3D-printed component can be approved.

In addressing these challenges, industry stakeholders are advocating for updated regulations that account for the unique characteristics of additive manufacturing. Collaborative efforts between companies and regulatory agencies can help develop more accommodating frameworks that mitigate risks while promoting innovation and safety.

Future Outlook: Integration with Emerging Technologies

The future of 3D printing in aerospace and automotive industries is poised for growth through integration with other emerging technologies, such as artificial intelligence (AI) and the Internet of Things (IoT). AI can optimize production processes by analyzing data in real-time, enhancing efficiency and quality control in 3D-printed components. Likewise, IoT devices can facilitate better monitoring of machinery and materials, leading to predictive maintenance and reduced downtime.

As these technologies converge, companies are likely to unlock new capabilities, further pushing the boundaries of what is achievable with 3D printing. The emphasis will not only be on improving manufacturing processes but also on fostering greater innovation that corresponds with the evolving demands of consumers and regulatory authorities.

Future Trends to Watch

Advancements in Material Science

- Development of bio-based and recyclable materials for 3D printing.

- New composite materials enhancing strength and versatility.

- Introduction of smart materials with adaptive properties.

Recent innovations in material science have significantly impacted 3D printing capabilities. These advancements include the creation of Bio-based and recyclable materials, which cater to an environmentally conscious market. As industries face increasing pressure to reduce their environmental footprint, the adoption of these materials is expected to rise sharply.

Additionally, researchers are now focusing on composite materials that combine polymers with other substances to enhance functionality. For instance, materials infused with natural fibers can offer increased strength without significantly raising costs, which is crucial for sectors like automotive and aerospace.

Integration of Artificial Intelligence

Artificial Intelligence (AI) is becoming a pivotal component in the field of 3D printing. The integration of AI allows for optimization in design and manufacturing processes. By analyzing vast amounts of data, AI can suggest design alterations that improve efficiency and material usage. This can lead to significant cost savings and better production timelines.

Moreover, AI-driven predictive maintenance tools are helping manufacturers minimize downtime. With real-time data analysis, businesses can anticipate equipment failures before they happen, thereby ensuring smoother operations and less disruption.

Personalized and Mass Customization

- Growth in demand for customizable products across various sectors.

- Applications in healthcare for personalized medical devices.

The trend of personalization has been gaining momentum, especially in consumer-driven markets. As technology evolves, the ability to produce customized items quickly and affordably is becoming more feasible. This trend is particularly visible in the healthcare sector, where personalized medical devices are revolutionizing patient care. Custom prosthetics and implants are being tailored to individual patients, improving comfort and effectiveness.

Furthermore, the rise of on-demand manufacturing allows businesses to cater to specific customer preferences without overproducing inventory. This transition not only enhances customer satisfaction but also reduces waste, aligning with sustainable practices.

Applications in Construction and Architecture

The construction industry is on the brink of a significant transformation driven by 3D printing technologies. Large-scale 3D printers are enabling the construction of entire buildings using innovative techniques. These methods can greatly reduce labor costs and construction times. Notably, projects like the 3D-printed houses have already been completed with remarkable success, showcasing the potential to address housing shortages rapidly.

In architecture, the creative possibilities expand as architects utilize 3D printing for intricate designs that traditional methods cannot achieve. This allows for more innovative structures and the incorporation of complex geometries, leading to aesthetically appealing and functional buildings.

Regulatory and Ethical Considerations

- Increased focus on intellectual property protection in 3D printing.

- Debates surrounding ethical manufacturing practices and safety standards.

As 3D printing technology proliferates, regulatory frameworks struggle to keep pace. The need for updated intellectual property laws is critical, given the ease of replicating designs. Many industry experts argue that clearer guidelines are necessary to protect creators and ensure fair use of printed products. This will foster innovation while maintaining respect for original designs.

Moreover, ethical considerations surrounding the use of 3D printing must be addressed. Issues such as safety standards for printed goods, especially in life-critical applications, demand thorough examination. As public awareness grows, manufacturers will be under increased scrutiny to adhere to ethical manufacturing practices without compromising quality or safety.